Side Entry Systems

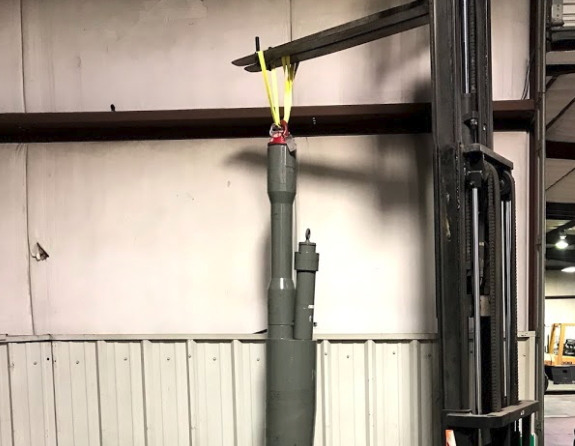

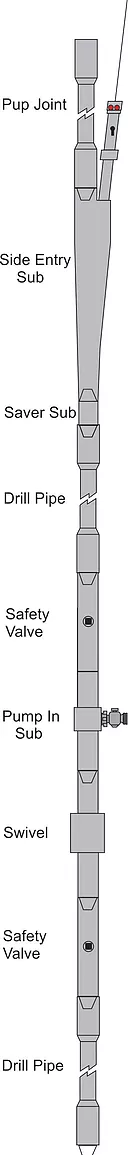

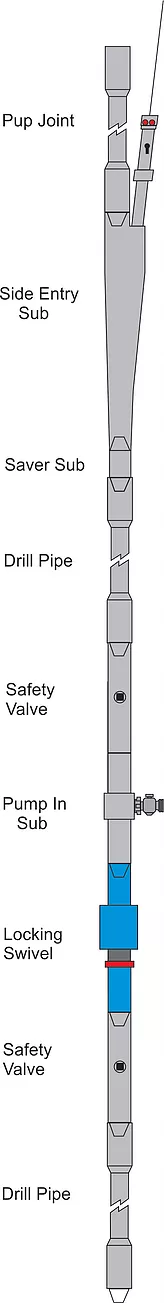

Wireline Control Systems provides a Side Entry System for well control during pipe recovery, fishing, and directional drilling applications. The Side Entry System was created to allow wireline operations through drill pipe without interference from the rig's top drive. The design permits the rig to reciprocate, rotate, and circulate the drill string while wireline operations are being performed. Pressure control is maintained throughout all operations. The wireline is wiped clean as it is extracted from the well bore. Swivels, standard or locking, are inserted in rig ups per application requirements.

WCS has Side Entry Systems ranging in sizes from 4 1/2" IF to 6 5/8" FH along with the ability to cross over to any size drill pipe.

WCS has Side Entry Systems ranging in sizes from 4 1/2" IF to 6 5/8" FH along with the ability to cross over to any size drill pipe.

Advantages of using Side Entry Sub:

- Keeps the wireline a safe distance from the traveling block and top drive

- Allows pumping and circulation at any time during wireline operations

- Wipes wireline clean as it is pulled from the well

- Wireline tools can be deployed through the top side

- The design of the tool allows for a straight pull on the drill pipe

- It can be run with a locking swivel for directional services

- Used in pump down operations

| Tool Size (In) | OD (In) | ID (In) | Torques (Lbs) | Tensile Yield (Lbs) | Safe Working Load (Lbs) |

|---|---|---|---|---|---|

| 3-1/2" IF | 12 | 2.5 | 11,100 | 543,000 | 490,000 |

| 4-1/2" IF | 12 | 3 | 31,700 | 1,268,963 | 954,260 |

| 5-1/2" FH | 12 | 3.375 | 33,000 | 1,448,407 | 1,000,000 |

| HT-55 | 15 | 3.375 | 52,600 | 1,448,400 | 1,100,000 |

| HT-65 | 15 | 4.125 | 73,400 | 1,448,400 | 1,200,000 |

| 6-5/8" FH | 15 | 4.125 | 47,000 | 1,448,400 | 1,200,000 |

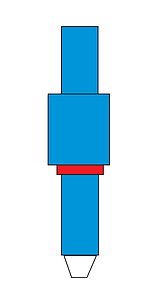

Mechanical Locking Swivel

Wireline Control Systems' Mechanical Locking Swivel allows the drill string to be "locked" into place when using a down hole motor for drilling. When a new orientation is needed for the drill bit, the Locking Swivel is disengaged, allowing the drill pipe to rotate. When the drill bit has been reoriented, the Locking Swivel is locked into place and drilling can resume at the new orientation.

To Unlock the Locking Swivel:

Disengage Mechanical Locking Swivel by setting the weight of the drill string on the rotary slips, slack off approximately 3 inches until the red locator sleeve )the visual indicator) bottoms out against the lower face of the swivel housing.

To Lock the Locking Swivel:

Lift blocks to engage the Locking Swivel. The red locator sleeve will move approximately 3 inches below the swivel housing.